About Us

Ditron Dental USA

Ditron Group, a precision machining world leader and the parent company for Ditron Dental was established in Israel in 1968. We believe a multi-disciplinary approach is the best catalyst for innovation and have teamed engineers, micro-machining specialists and top-notch clinicians to drive our research, development and production of high-end dental implant-based solutions.

Ditron Dental is founded on the basis of more than 50 years of experience in the design, production and delivery of ultra-precise mission critical products for the aerospace, aeronautical, automotive and medical device industries. Outstanding precision and exceptional quality are essential parts of our corporate DNA.

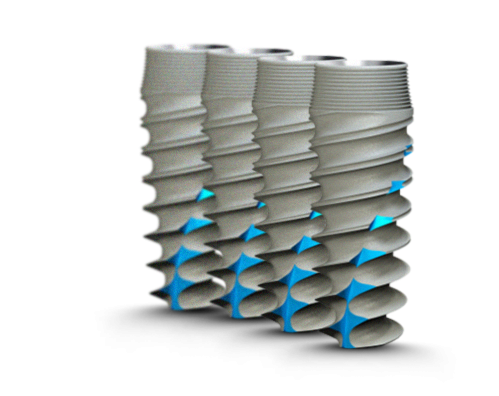

Precision Built In

For more than 50 years, Ditron Group has designed and produced high precision machined components for the aerospace, aeronautics, automotive and medical device industries. The company owns and operates out of a 60,000 SF state of the art facility in Ashkelon, a coastal city in the Southern District of Israel. They have been one of the leading companies in the design, production and JIT “Just in Time” delivery of ultra-precise mission critical products.

Our products have been installed in some of the most extreme and challenging environments in which failure is unacceptable, including Tesla, Daimler, Jaguar, Ferrari F-1, Robert Bosch Corp, BMW and Mercedes-Benz. With state-of-the-art technology and in-depth process control, we attain production in single micron level accuracies. We strive for the highest quality in all our accomplishments.

Commitment to Quality & Safety

Dental implant product safety and reliability are at the forefront of all our activities. Our quality management system controls the in-house dental implant production process with aerospace accuracy integrated with biomechanical excellence and stringent medical production procedures.

From raw material to clean room packaging, all production stages are made in our own state-of-the-art facility.

Each and every step is closely monitored and constantly validated to ensure product safety and reliability. This advanced quality assurance system aims to assure that our performance of Zero-PPM “Zero Defects per Million Parts” proven capability will be sustained.

Inspection & Certification

All dental implants, prosthetic components and instruments undergo a comprehensive internal testing and inspection process that fully complies and furthermore exceeds all applicable regulations and standards.

Prior to cleanroom packaging, the dental implants, prosthetic components and instruments are mechanically washed and disinfected in accordance with the highest standards. The dental implants are then delivered to the cleanroom for packaging.

These facilities are ISO 14644-1 “Class 7” compliant, for particle counts of less than 1 per million/m³. Ditron Dental is certified under EN ISO 9001:2008, SN EN ISO 13485:2012 MDD 93/42/EEC Annex II and is authorized to use the CE mark on all Ditron Dental products. All products are 510 (k) cleared by the FDA.

Advisory Board

Dr. Joel L. Rosenlicht, DMD

Robert Miller, DDS

Dr. Michael S. Block, DMD

Dr. Bernee Dunson

Resources

Visit our digital resource library to review and download product catalogs, brochures, technique manuals, videos, articles, and much more.

Education & Events

We place a premium on the science behind our products and are at the forefront of education with live surgery courses from 1-day surgical to 3-day live patient courses.

Lifetime Warranty

Ditron Dental provides a lifetime warranty for all its dental implants and prosthetic components when used in accordance with the supplied Instructions for Use (IFU) and the company’s protocols.